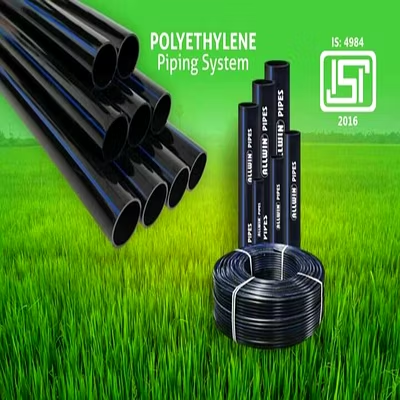

HDPE Pipes & Fittings HSN:39172110

-

Product is not available

Country Of Origin : India

Product Introduction: High-Density Polyethylene (HDPE) Pipes & Fittings

How HDPE Pipes & Fittings Fulfill Client Needs

Product Classification

Parameter Details

HSN Code 39172110 (Tubes of polyethylene); 39174000 (Fittings for pipes of plastics)

Category Building Materials / Industrial Plastics

Subcategory Piping Systems / HDPE Pipes & Fittings

Product Properties Technical Properties

• Minimum Required Strength (MRS): 10.0 MPa

• Hydrostatic Design Basis (HDB): 11 MPa

• Tensile Strength at Yield: 23 MPa

• Elongation at Break: >600%

• Modulus of Elasticity: 200 MPa (50 years)

• Flexural Modulus: 1000 MPa

• Thermal Expansion Coefficient: 1.3 x 10⁻⁴ °C⁻¹

• Service Life: Up to 100 years

Chemical Properties

• Material: High-density polyethylene (HDPE)

• Density: 930–970 kg/m³

• Melting Point: ~132°C

• Resistant to acids, alkalis, salts, and organic solvents

• Non-toxic and suitable for potable water

Physical Properties

• Color: Typically black (UV-stabilized), blue, or other colors for coding

• Outer Diameter Range: 16 mm to 1200 mm (customizable)

• Wall Thickness: As per pressure rating (PN 2.5 to PN 25)

• Smooth internal surface (low friction loss)

• Lightweight (density ~0.95 g/cm³)

Mechanical Properties

• High impact and abrasion resistance

• Excellent flexibility (can accommodate ground movement)

• High fatigue resistance (suitable for cyclic loading)

• Puncture and crack resistance

Manufacturing Methods

• Raw Material Preparation: Selection and quality check of HDPE resin pellets.

• Extrusion: Resin is melted and extruded through a die to form continuous pipes.

• Sizing & Cooling: Pipes are sized and cooled (water or air) to retain shape.

• Cutting & Inspection: Pipes are cut to length and inspected for quality.

• Fittings Fabrication: Injection molding or fusion welding to create elbows, tees, flanges, etc.

• Quality Control: Pressure testing, dimensional checks, and visual inspection.

Industrial Uses

• Potable water supply and distribution

• Irrigation and agricultural pipelines

• Sewage and drainage systems

• Industrial fluid and gas transport

• Mining and slurry lines

• Cable ducting and conduit

• Firefighting systems

• Marine and underwater pipelines

Market Overview: Global Demand & Indian Supply

• Global Demand: Valued at USD 21.09 billion in 2024, projected to reach USD 30.80 billion by 2033 (CAGR 4.09%). Growth driven by infrastructure, agriculture, and water management projects worldwide.

• Indian Supply: India is a major manufacturer and exporter, with a strong presence in Asia-Pacific (44.1% market share in 2024). Indian HDPE pipes are recognized for quality, competitive pricing, and compliance with international standards.

Packaging & Logistics

• Packaging: Supplied in coils (for smaller diameters), straight lengths (sticks), or on reels. Fittings are packed in cartons or crates.

• Shipping Methods: By truck (flatbed, LTL, or enclosed trailer), containerized sea freight, or air freight for urgent orders.

• Dimensions & Weight:

- Pipe length: Standard 6m, 12m, or custom.

- Weight: Calculated as per pipe size and wall thickness (e.g., 2.69 kg/m for 100 mm OD, 90 mm ID).

- Fittings: Vary by type and size.

• Bulk Packaging: Palletized and shrink-wrapped for protection and easy handling.

• Storage: Store in cool, shaded areas; avoid direct sunlight for extended periods.

Preferred INCO Terms

• FOB (Free On Board)

• CFR (Cost and Freight)

• CIF (Cost, Insurance, and Freight)

These terms provide flexibility to clients based on their shipping and insurance preferences.

Popular Products

• Rigid PVC Pipe

• Gas Pipe

• Elastomeric Ring Socket Pipe

• HDPE Pipe

• SWR Pipe

• UPVC Plumbing Pipe

• CPVC Pipe(Hot Shield)

• Conduit Pipe(Shock Shield)

• Column Pipe

• MDPE Pipe

• Lateral Pipe

• UPVC Casing Pipe

• Underground Sewerage Pipe

• HDPE Sprinkler Pipe

• PVC Fittings

• SWR Fittings

• Fabricated Fittings

• HDPE Fabricated Fittings

• CPVC Fittings(Hot Shield)

• Conduit Fittings(Shock Shield)

• Water Tanks

• PLB Duct

• DWC Pipe

• Concealed Valve