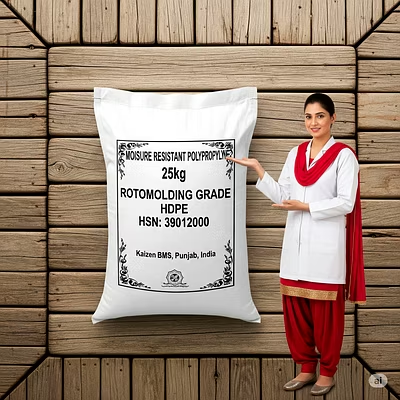

HSN:39012000 > HDPE in Primary Forms

-

Product is not available

Country Of Origin : India

HDPE in Primary Forms:

High-Density Polyethylene (HDPE) in primary forms is a versatile, high-performance thermoplastic resin offered as granules, pellets, or powders. Widely recognized for superior strength, chemical resistance, and ease of processing, HDPE is essential for manufacturers globally across packaging, piping, film, and molded component industries, supporting innovation in construction, automotive, and consumer markets.

Usability

HDPE in primary forms ensures uniform quality, reliable supply, and broad application flexibility. Its high melt strength and process stability enable seamless extrusion, molding, and film blowing operations. Precise specifications covering film, injection, blow molding, and pipe grades to meet industry. The resin’s low moisture absorption, impact resistance, and customizable formulations provide products suitable for food contact, pharmaceuticals, construction, and industrial packaging. Vacuum-sealed, moisture-proof bags optimize shelf life and logistics. Kaizen BMS offers documentation, certification, and scalable loads, ensuring international compliance, fast turnaround, and the trust of global manufacturers sourcing primary HDPE.

Common Global Trade Names

• HDPE Resin

• Polyethylene Granules

• HDPE Pellets

• Virgin HDPE

• HDPE Film Grade, Blow Molding Grade, Injection Grade, Pipe Grade

Available Types for Global Trade

• Film Grade HDPE

• Blow Molding Grade HDPE

• Injection Molding Grade HDPE

• Pipe Grade HDPE (PE80, PE100)

• Rotomolding Grade HDPE

• Cross-linkable HDPE (PEX)

• Black/UV Stabilized HDPE

HSN Code, Category & Sub-category

• HSN Code (8 digits): 39012000

• Category: Plastics in Primary Forms

• Sub-category: Polyethylene, high density (HDPE) in primary forms

Technical & Data Points

Physical Properties

• Density: 0.941–0.965 g/cm³

• Melting Point: 130–137°C

• Natural color: Translucent to white

• Particle size (granule): 2–5 mm

• Water absorption: <0.01%

Chemical Properties

• Inert to acids, alkalis, and many solvents

• UV stabilizers or carbon black (optional for outdoor use)

• Volatile matter: <0.1%

• Oxidation resistance: High

• Food-grade: Compliant grades for packaging

Technical Properties

• Melt Flow Index (MFI): 0.03–30 g/10min (varies by grade)

• Excellent electrical insulation

• Compatible with blow/injection/extrusion processes

• High processability across thermoforming and rotomolding

Mechanical Properties

• Tensile strength: 20–37 MPa

• Flexural modulus: 800–1,500 MPa

• Impact resistance: High, withstands low temperatures

• Elongation at break: 500–1,200%

• Hardness: Shore D 60–67

Manufacturing Methods

• Polymerization of ethylene under controlled pressure & catalysts (Ziegler–Natta or Metallocene)

• Pelletizing techniques: Underwater or strand cut

• Additive blending (antioxidants, UV, slip/antiblock as per grade)

• Packaged in moisture-barrier woven sacks or FIBCs (jumbo bags)

• Test & quality certification batch-wise

Industrial Use

• Blown films for packaging, liners, and agricultural covers

• Industrial and potable water pipes

• Bottles, drums, cans via blow molding

• Injection-molded crates, bins, automotive parts

• Rotomolded tanks, playground equipment

• Wire & cable jacketing

Market Overview: Global Demand & Kaizen BMS Role

• HDPE is among the world’s fastest-growing commodity resins, high demand in Asia, North America, EU, and Middle East

• Construction, packaging, and infrastructure are key drivers

• Indian HDPE sees rising exports due to quality and price competitiveness

• Kaizen BMS delivers export-grade HDPE with customizable specs, reliable and on-time global shipments, and full compliance with international standards

Packaging & Logistics

• 25kg moisture-resistant woven sacks (standard)

• 500kg/1,000kg FIBCs for bulk shipments

• Palletized loads, shrink-wrapped for containerization

• Export-ready, batch traceability, and barcoding as per client need

Shipping Dimensions & Weight

• Standard: 25kg bags, 1,000kg per pallet (40 bags)

• 20 ft container holds ~16–20 MT (metric tons)

• 40 ft container: up to 28 MT, packed in bags/jumbo bags

Certificates Required in India for Export

• BIS/ISI certification for specific end-uses

• Certificate of Analysis (COA) per batch

• ISO 9001:2015 for manufacturing facility

• REACH/RoHS/food-contact compliance (as per destination)

• SGS/Intertek inspection, Material Safety Data Sheet (MSDS)

Preferred INCO Terms

• FOB (Free on Board)

• CRF/CFR (Cost and Freight)

• CIF (Cost, Insurance, Freight)

• Export dispatch from Mundra, Nhava Sheva (JNPT), Chennai

Payment Methods

• 100% Advance payment (new/small buyers)

• Sight LC (Letter of Credit at sight) for established/bulk orders

• Advance plus Sight LC combination for contract shipments

GST Implication in FY.2025-26

• The applicable GST rate is 18% under this HSN code

Dispatch Possible From Indian Ports

• Mundra Port

• Nhava Sheva (JNPT) Port

• Chennai Port

Company Profile – Kaizen BMS

Kaizen BMS, a Government of India-recognized exporter, excels in the global trade of premium industrial products and raw materials. Our dedicated export unit is committed to reliability, consistency, and transparent service, handling customized and contract manufacturing from source to shipment. With strong compliance, technical documentation, and tailored supply chain solutions, Kaizen BMS ensures long-term, value-driven, and partner-centric relationships for discerning buyers worldwide.