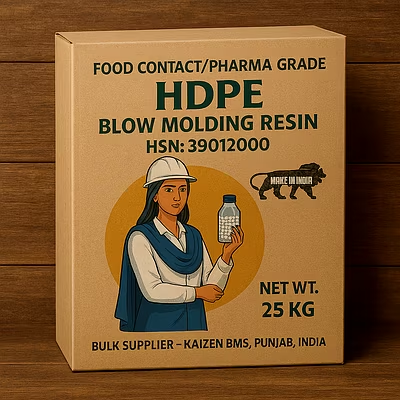

HSN:39012000 > HDPE Blow Molding Resin

-

Product is not available

Country Of Origin : India

HDPE Blow Molding Resin: Introduction

HDPE Blow Molding Resin is a high-strength thermoplastic polymer engineered for producing robust, lightweight hollow articles. Designed for outstanding processability and dimensional stability, this resin ensures consistent quality in manufacturing bottles, drums, automotive, and large industrial containers.

Importer’s Benefits

Importers enjoy maximum value with HDPE Blow Molding Resin’s exceptional yield and reliability, minimizing production waste and costly downtime. Competitive sourcing from Kaizen BMS secures genuine, traceable raw material that conforms to international standards—ensuring fewer rejections and regulatory hurdles. The resin’s versatility allows manufacturers to efficiently produce a range of high-margin products with excellent mechanical properties and reduced material-to-output ratios, optimizing both costs and product quality. Consistent pellet morphology and moisture resistance ensure smooth processing, reducing machine maintenance expenses. Scalable supply, technical documentation, and reliable shipment help maintain steady production schedules and secure supply chains, driving profitability and procurement efficiency for every importer.

Global Trade Common Names

• HDPE Blow Molding Resin

• High-Density Polyethylene BM Grade

• Polyethylene HDPE BM Granules

• HDPE BM Pellets

• HM-HDPE (High Molecular Weight HDPE)

Available Types for Global Trade

• General Purpose Blow Molding Grade (small and large containers)

• High Molecular Weight/High Flow Grade (drums, fuel tanks)

• Food Contact/Pharma Grade

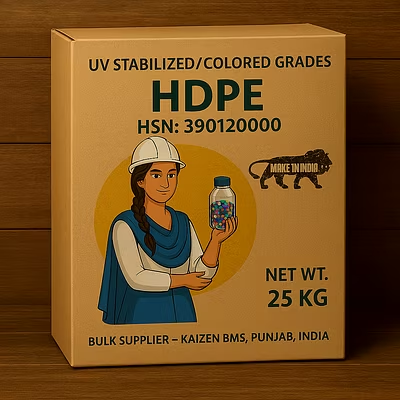

• UV Stabilized/Colored Grades

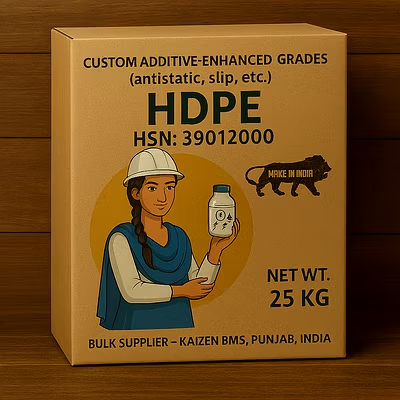

• Custom Additive-Enhanced Grades (antistatic, slip, etc.)

HSN Code, Category & Subcategory

• HSN Code (8 digits): 39012000

• Category: Plastics in Primary Forms

• Sub-category: Polyethylene, high-density (HDPE), in primary forms

Physical Properties

• Density: 0.945–0.965 g/cm³

• Pellet size: 2–5mm diameter; dust and moisture-free

• Melt index (MFI): 0.04–1.0 g/10min (as per grade)

• Natural white/translucent; can be compounded as per demand

• Excellent chemical and impact resistance

Chemical Properties

• Non-toxic, food-grade variants available

• Resistant to acids, alkalis, most solvents, and hydrocarbons

• Additive compatibility: UV, color masterbatch, antistatic, antioxidants

• Low water absorption (<0.02%)

Technical Properties

• High melt strength for uniform wall thickness in finished goods

• Excellent environmental stress crack resistance (ESCR)

• Stable under rapid cooling and continuous production cycles

• Consistent processing in both single- and multi-layer blow molding lines

• Wide processing temperature: 160–210°C

Mechanical Properties

• Tensile strength: 20–27 MPa

• Flexural modulus: 900–1100 MPa

• Impact resistance: Excellent at temperatures down to -50°C

• Retains shape and dimensional stability under heavy load

Manufacturing Methods

• Ethylene polymerization using Ziegler–Natta or Metallocene catalyst in reactors

• Granulation and blending with required stabilizers/additives

• Degassing and homogenization for uniformity

• Quality batch testing (melt flow, contamination, pellet morphology)

• Packed in moisture-proof bags or FIBCs for export

Industrial Use

• Blow molded packaging: bottles (water, milk, chemicals), drums, carboys, jerry cans

• Automotive: fuel tanks, ducts, reservoirs, battery cases

• Toys, coolers, portable containers, storage bins

• Large industrial and agricultural tanks

Market Overview: Global Demand & Kaizen BMS Indian Supply

• Global blow molding resin demand is rising, led by packaging, chemical, and beverage sectors

• Major importers: USA, Germany, Japan, China, Middle East, Africa

• India is a key hub due to cost-competitiveness, modern plants, and broad compliance

• Kaizen BMS offers high-volume, quality-assured supply tailored to buyer requirements, facilitating rapid contract and repeat orders

Packaging & Logistics

• Standard export: 25kg moisture-resistant woven bags

• Jumbo FIBCs: 500–1,200kg per bag for bulk buyers

• Palletized and shrink-wrapped for container loading

• Each bag labelled with batch, date, and technical grade

Shipping Dimensions & Weight

• 25kg bags; 40 bags per pallet; ~1 MT/pallet

• 20’ container: 16–18 MT; 40’ container: 25–28 MT (exact based on packing)

• Bags/pallets shrink-wrapped; FIBC in lined containers for sea/air

Certificates Required for Export (India)

• BIS/ISI product certification (if required by buyer/market)

• ISO 9001 (Quality Management) for manufacturer

• Food-contact/FDA/EC compliance certification for food/pharma grades

• Certificate of Analysis (COA), Material Safety Data Sheet (MSDS)

• SGS/Intertek third-party inspection by requirement

Preferred INCO Terms

• FOB (Free on Board)

• CFR (Cost & Freight)

• CIF (Cost, Insurance & Freight)

Payment Methods

• 100% Advance for initial/small orders

• Sight Letter of Credit (Sight-LC) for bulk/regular shipments

• Combination of Advance + Sight LC for ongoing contracts

GST Implication in India

• HSN 39012000: 18% GST for domestic; exports zero-rated (eligible for input tax credit/refunds)

Dispatch Possible From Indian Ports

• Mundra

• Nhava Sheva (JNPT)

• Chennai

• Amritsar (for land/central Asia)

• New Delhi (ICD/dry port)

• Other ports/ICDs as per routing and buyer demand

Kaizen BMS Company Profile (for Buyer)

Kaizen BMS, a Government of India-recognized exporter, is trusted globally for the supply of high-quality industrial raw materials and plastic resins. Our export unit delivers customized, contract, and merchant export solutions with robust technical support, compliance, and logistics management. We offer scalable, long-term partnerships to buyers worldwide, emphasizing product integrity, documentation, and transparency for seamless, dependable procurement.