Bituminous Membrane (Waterproofing Material) HSN: 68071090

-

Product is not available

Country Of Origin : India

Product Introduction: Bituminous Membrane (Waterproofing Material) HSN: 68071090

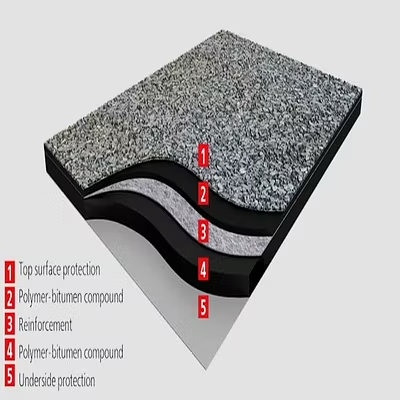

Bituminous Membrane is a high-performance, polymer-modified waterproofing sheet composed of bitumen and reinforcing materials. Engineered for superior flexibility, chemical resistance, and longevity, it offers a seamless waterproof barrier ideal for roofs, basements, bridges, and foundations, ensuring top-tier structural protection in demanding climates and industrial environments.

Usability & Importance for Buyers

Bituminous Membrane is indispensable for modern construction and infrastructure, delivering exceptional water and moisture resistance to prolong building life and reduce maintenance. Its ease of installation, compatibility with diverse substrates, and proven durability offer buyers cost-effective, reliable waterproofing solutions. The product safeguards structural integrity, prevents water ingress, and minimizes damages from humidity, thus enhancing asset value and supporting sustainable development in both new construction and renovation projects.

Product Classification Parameter Details

HSN Code 68071010

Category Waterproofing Materials

Subcategory Bituminous Membrane Sheet

Product Details

Technical Properties

• Thickness: 2mm, 3mm, 4mm (customizable)

• Roll Length: 10m standard

• Tensile Strength: ≥500 N/5cm (longitudinal); ≥300 N/5cm (transverse)

• Elongation: ≥30%

• Water Absorption: ≤0.2%

• UV and chemical resistant

Chemical Properties

• Composition: Distilled bitumen, polymers (APP/SBS), reinforcement (polyester/glass fiber)

• Softening Point: ≥150°C (APP), ≥90°C (SBS)

• Resistant to acids, alkalis, salts, and organic solvents

Physical Properties

• Appearance: Black sheet, smooth finish or mineral-surfaced

• Weight: 3kg/m² to 5kg/m² (varies by grade)

• Flexibility: Excellent; flexible at sub-zero temperatures

• Waterproof: Passes multi-hour water immersion tests

• Dimension Stability: High

Mechanical Properties

• Tear Resistance: ≥150N (standard)

• Puncture Resistance: High—suitable for high-traffic surfaces

• Root and fungi resistance: Advanced protection

Manufacturing Methods

• Bitumen modification with synthetic polymers (e.g., atactic polypropylene or styrene-butadiene-styrene)

• Reinforcement insertion (polyester/glass fiber mat)

• Lamination under controlled temperature and pressure

• Surface finishing (sand, polyethylene film, or mineral granules)

• Automated rolling, sealing, and quality-assurance checks

Industrial Uses

• Roofs (flat and pitched)

• Basements and tunnels

• Foundations and retaining walls

• Water tanks and wet areas

• Bridges, viaducts, and podiums

Market Overview: Global Demand & Our Indian Supply Role

The global demand for bituminous membranes is robust, fueled by infrastructure expansion, urbanization, and climate resilience initiatives. International contractors and developers seek reliable, certified waterproofing solutions. India is a leading supplier, exporting high-quality membranes that comply with global standards. Kaizen BMS delivers consistent supply, bespoke solutions, and technical support to premium clients worldwide, ensuring long-term partnerships and on-time fulfillment for major projects.

Packaging & Logistics

• Standard Packaging: Rolls (1m width x 10m length); protective plastic/woven sleeves

• Shipping Dimensions: Each roll ~110cm length x 18cm diameter

• Weight per Roll: ~30–50kg depending on thickness and finish

• Palletizing: Up to 25 rolls per standard pallet

• 20ft Container Capacity: ~9–11 MT (varies by roll thickness)

• Storage: Cool, dry, shaded area; do not stack over two pallets

• Lead Time: 1–2 weeks for standard export orders

Preferred INCO Terms

• FOB (Free On Board)

• CFR (Cost and Freight)

• CIF (Cost, Insurance, and Freight)

Company Profile: Kaizen BMS

Kaizen BMS is a Government of India-recognized exporter with a dedicated Export Unit specializing in the global trade of high-quality industrial products and raw materials. With a diverse portfolio, we cater to industries worldwide, offering customized, contract manufacturing, and merchant exporting solutions for premium clients. As a reliable and consistent supplier, we focus on long-term partnerships, technical excellence, and consistently meeting global demand with integrity and service excellence.